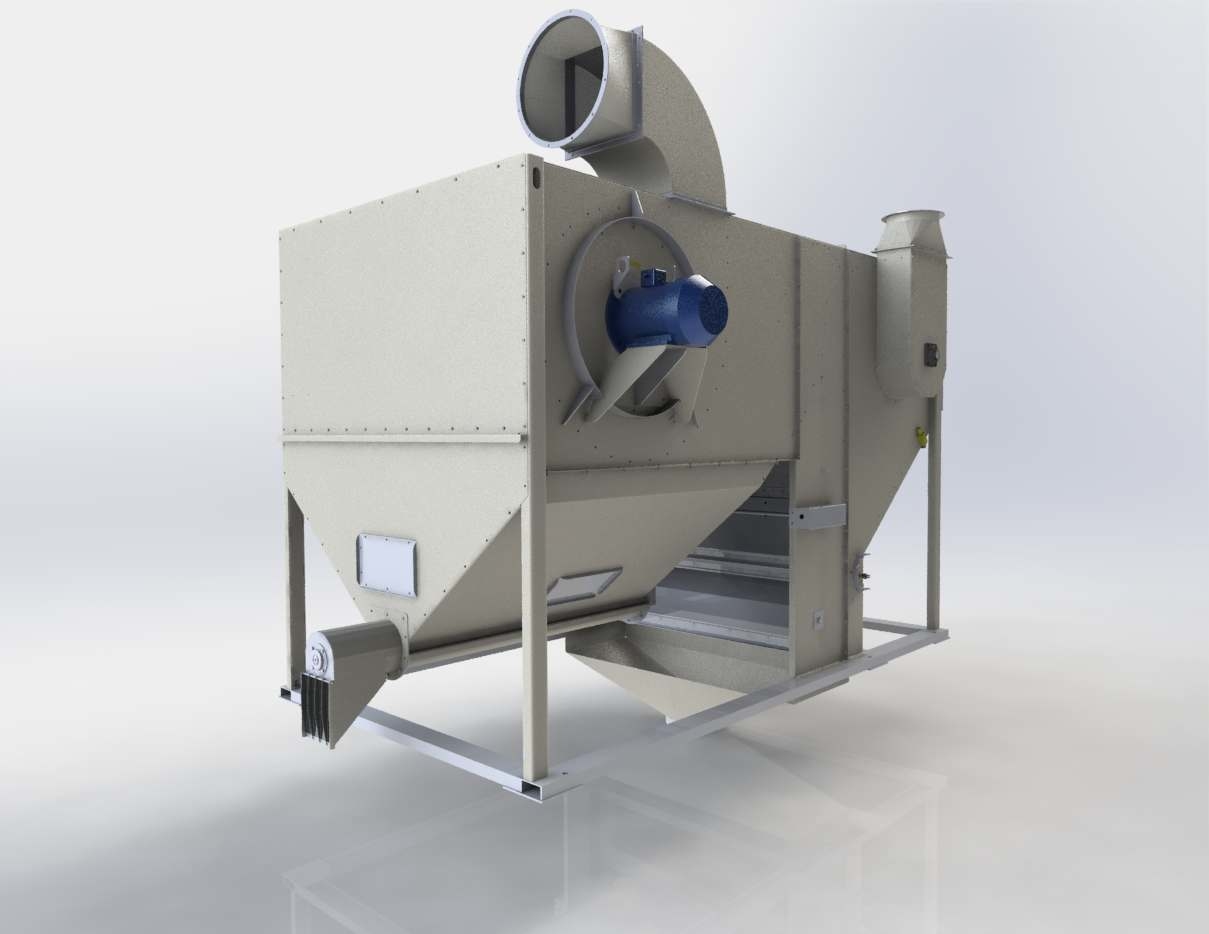

Description

The grain pretreatment separator (SPP) is designed for pretreatment of grain, leguminous and other crops.

the Separator is installed as a part of technological lines of grain-cleaning complexes of agricultural enterprises, elevators, flour-milling and grain production.

At the heart of the grain cleaning separator sppz-60 implemented the principle of separation from the grain of impurities that differ from it in width, thickness and aerodynamic properties.

< p>grain Cleaning separator sppz-60 consists of a drum and a powerful pneumatic separation channel, which is attached to the auxiliary equipment. At the entrance to the separator joins silnoproud to ensure the delivery of the processed material into a hopper, which is made with one-way slope, where the installed liner strip that prevents the Erasure of the base of the hopper flow of grain during long-term operation.

from the receiving hopper, the grain mass flows by gravity into the mesh drum, passes it and enters the sifting chamber, where it is evenly distributed and through the metering valve enters the aspiration channel, in which the grain mass is cleaned from small impurities.

Large impurities are output through the large impurities output channel. After aspiration cleaning, the cleaned grain through the lower tray of the pneumatic separation channel is taken either to the storage bin or to the transporting device, depending on the technological scheme of cleaning.

the impurities Extracted from the cleaned material, together with the main air flow, pass through the cyclone built into the aspiration system (BO-10), are deposited in it, and the air is removed from the room through the fan by means of air ducts. Light impurities are removed through the screw.

Подписаться на наш канал

Подписаться на наш канал